Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

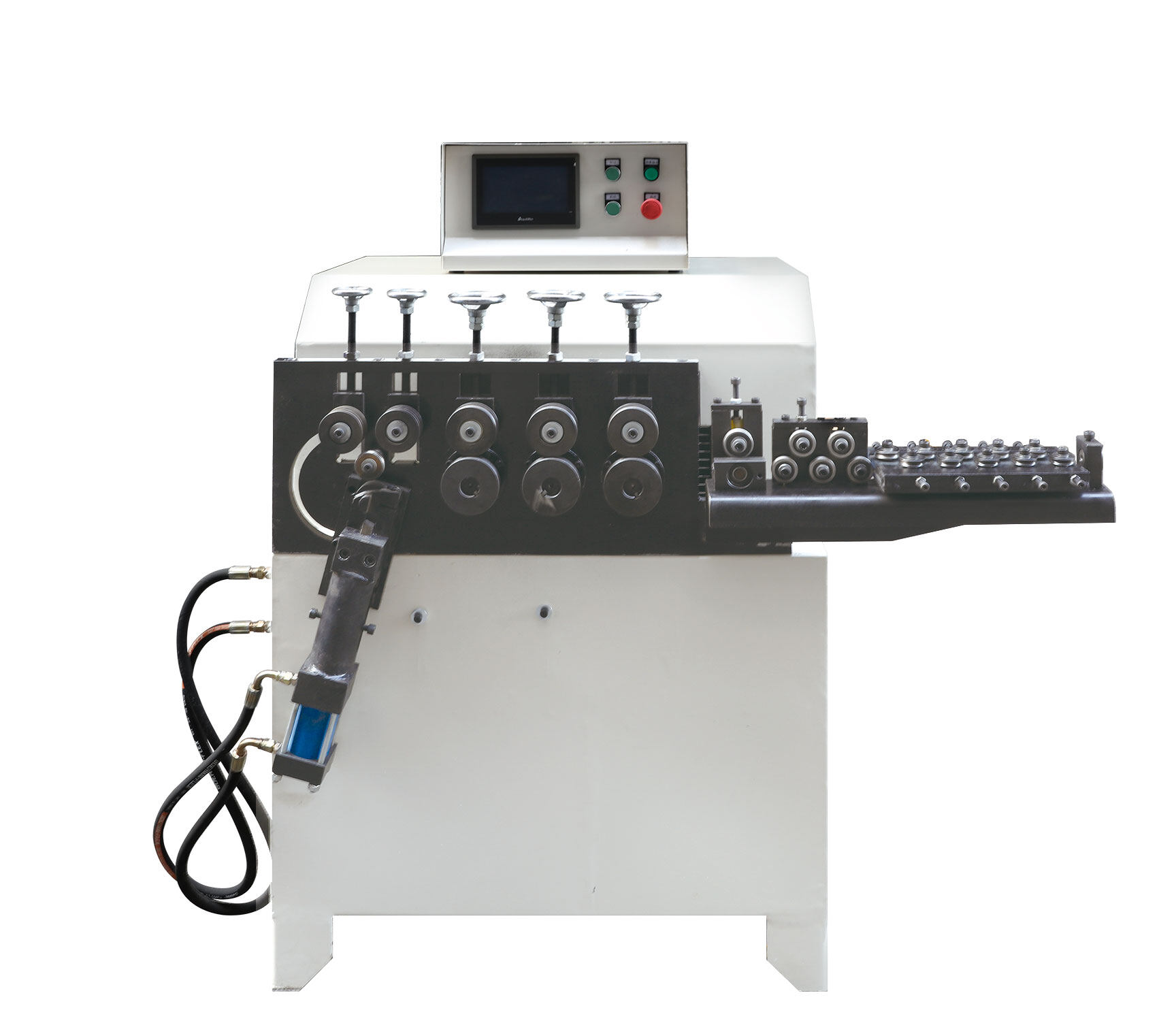

three phase welding machine

Wire Ring Making Machine

This machine is widely suitable for coiling various wire rods into circles, semicircles or arcs at any angle (concentric angle). With special molds and adjustable pressure wheels, it can also produce square and oval workpieces; wire rods with non-circular cross-sections, The plate can be processed only by replacing the wire adjustment wheel, wire feeding wheel, crimping wheel and cutter. It is used to improve product quality in industries such as cement poles, mining air ducts, environmental protection dust removal skeletons, fan grilles, lampshades, handicrafts, flowerpot racks, luggage fasteners, daily hardware and kitchen utensils (such as stove racks, wine/cup racks), etc. The first choice equipment to reduce production cost and increase production capacity. 1. The fully automatic circle machine controller is independently designed and produced by our company. It adopts single-chip integrated control, touch switches to adjust parameters arbitrarily, 15 kinds of parameter storage functions, and mathematical display, which saves time, facilitates management and improves production efficiency. 2. The key parts of the machine adopt imported components to ensure the service life of the machine. Among them, the electromagnetic oil valve, oil pump and oil pump motor are made in Taiwan, and the encoder is imported from Japan. 3. This machine has the characteristics of stability, speed and accuracy, and has the advantages of fast, slow and smooth feeding. Smooth: All are hydraulic transmission, cycloidal motor with a torque of 477Nm, no need for gear assist, which can reduce the gear gap; Fast: the line speed can reach up to 35~40m/min; Accurate: The error of the circumference of the circle is ±0.50mm. 4. The machine is a box-shaped structure with good rigidity, and the hydraulic transmission part is flexible and reliable. 5. The control box is equipped with functions such as fast feeding, shortening, manual cutting, automatic stop, and calling. 6. Equipped with a water-passing device to keep the oil temperature stable, avoid hot weather and long-term work to make the oil temperature too high, and further ensure product accuracy and uninterrupted work. Name Diameter (MM) Ring Diameter Inner Diameter (MM) Power (KW) Wire speed (M/MIN) Dimensions of the host machine (MM) 1-6 circle machine 1-6 55-850 1.5 20-40 1380×880×1400 2-8 circle machine 2-8 65-850 2.2 20-40 1380×880×1400 2-10 circle machine 2-10 100-850 3.0 20-40 1680×830×1450 8-13 circle machine 8-13 120-850 5.5 20-40 2320×950×1500 8-16 circle machine 8-16 130-850 7.5 20-40 2400×1100×1600 Servo circle machine 1-12 55-1000 2.0 40-45 1300×900×1400 Flat steel ring machine 2.4*8 2*6 120-900 7.5 2600×1000×1800 Hollow tube ring machine 10-20 (wall thickness 1-2) 300-1000 7.5 2600×1000×1800 The above parameters are for reference only. Exceeding the requirements of the above specifications, it can be customized by special plane.