Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

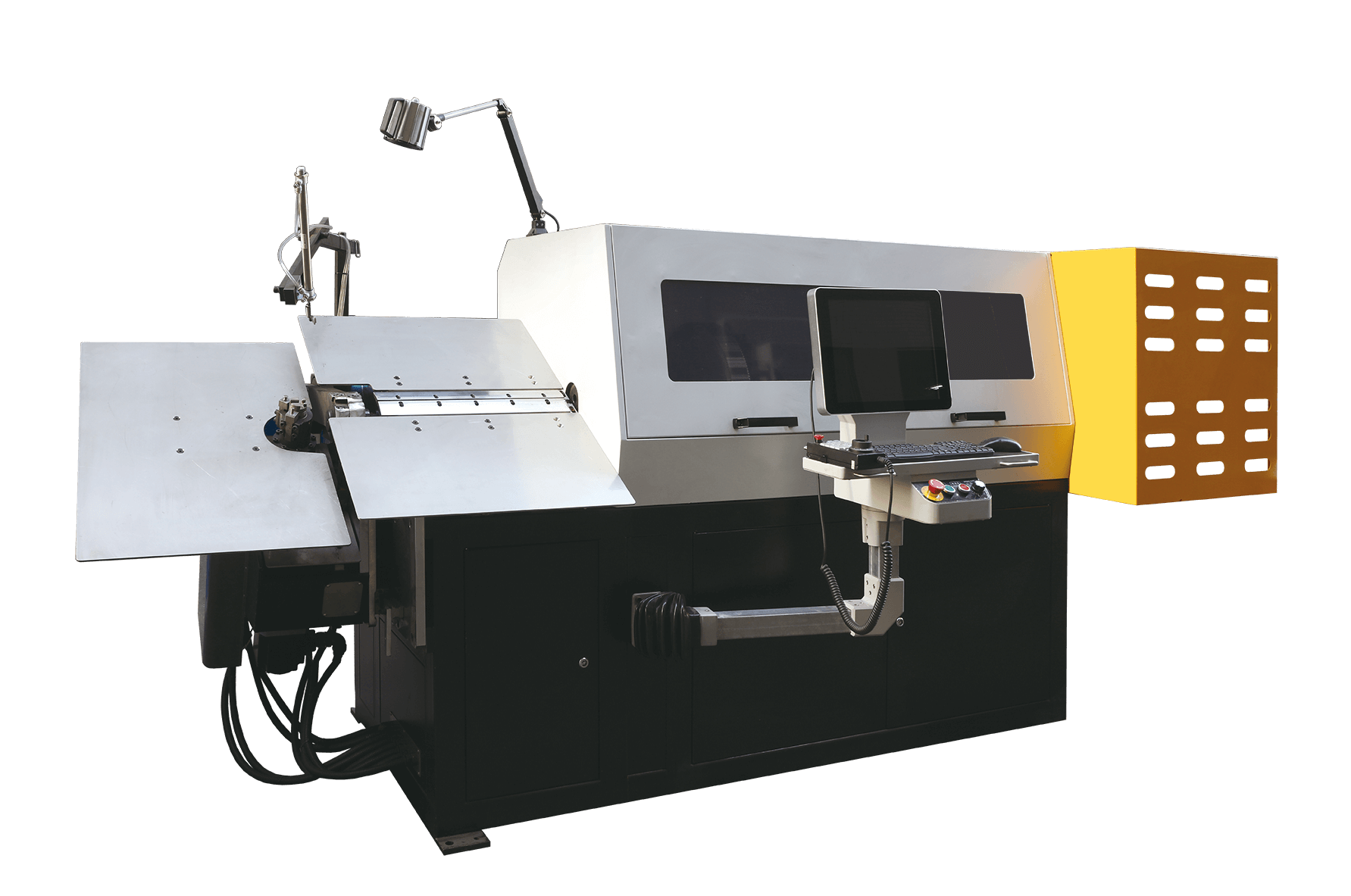

WIRE BENDING MACHINE

WIRE BENDING MACHINE

(24)The cnc wire bending machine must have wire feeding equipment, which can be operated on the CNC machine tool computer to make the feeding more accurate; it can be fully automatic wire feeding, straightening, sheet metal bending, breaking, and uninterrupted production; easy to use, Novices can usually learn it in 3-5 days, the production is stable, and the production speed is efficient and convenient; the actual operation is simple and easy to change, and it can be used according to the material, wire diameter, length, and appearance of the processed steel parts. Suitable speed; operation should be simple, only need to change tools when producing different products; 3d wire bending machine is well-equipped, with high precision and long service life.

The cnc wire bending machine is suitable for processing the wire diameter range, which can produce 3-16mm wire. The 2D bending machine can only realize a single product of the bending plane, while the 3D bending machine can make multi-dimensional and multi-angle forming products; Different manufacturers have differences in the technology of CNC wire bending machines, and the efficiency of wire processing and bending is quite different, which directly affects the production efficiency of enterprises. Our cnc wire bending machine adopts innovative rotor without motor technology, which can realize 360-degree rotation without turning the wire, making the overall load of the equipment lighter, the operation speed significantly improved, and the production efficiency is higher than that of domestic counterparts. Twenty percent or more.

Automatic cnc wire bending machine factory from China, We are sincerely looking forward to cooperate with customers all over the world.

The Advancements and Applications of Wire Bending Machines

Wire bending machines, also known as wire forming machines, are innovative devices that have revolutionized the manufacturing industry. These machines automate the process of bending wires into complex shapes, offering accuracy, speed, and efficiency. This article explores the advancements and applications of wire bending machines, highlighting their role in various industries.

Iron Wire Bending Machine

A good iron wire bending machine should be able to process different diameters of wires and different kinds of materials. The installation and layout are relatively convenient.

380 power supply voltage 2.5-6mm stainless steel wire diameter 2D wire bending machine for sale

Jinchun Machinery's CNC wire bending machines are built with robust materials and components, ensuring durability and long-term reliable performance even in demanding production environments.

Head-Rotating 3D Wire Bending Machine

Relying on a strong transmission system like the wire feeding motor, can make the wire rotation more quickly and stable. So it can increase the production efficiency.

3D Wire Bender

The quality of the 3D wire bending machine itself is indispensable when the selection, but also the operating system matched with it.

3d wire bending machine for sale

The emergence of 3D wire bending machines has changed the production process and cost of many enterprises. It is not only a way to increase production capacity, but also a way to reduce labor costs

Wire-Rotating 3D Wire Bending Machine

The wire bending machine is equipped with a professional servo motor, which drives the wire feeding wheel to rotate and controls each step of forming by the computer system.

3D Cnc Wire Bending Machine

The bending speed of the machine is controlled by the microcomputer. The different specifications can be achieved through various commands issued.

Wire Bender Machine

This is because even though the wire bending machine is of high quality, it must inevitably have some internal defects, which is a normal phenomenon during the use and maintenance process of a production machine.

China Cnc Wire Bending Machine

This CNC wire bending machine is suitable for the forming and processing of various wire products such as springs and pulls baskets. With functions of automatic wire feeding, straightening, bending, and one-time forming, it also has high precision and good performance.

Cnc Wire Bending Machine For Sale

When troubleshooting a machine, you must first understand and analyze what could be the causes that led to its failure. After determining the cause, you can then begin formulating solutions.

2D Wire Bending-Welding Machine

2D CNC wire bending machine with butt welding Specifications: Machine Model 2-6mm Power Supply 3Phases 4 wires+ground wire,380V,50HZ Wire Straightening Wheel Quantity 22 groups (made of Cr12) Bending Mold Made of SKD11/51, hardness is 62◦ Wire Feeding Wheel Quantity 3 groups (made of Cr12, heat processed ,hardness is 58◦) Servo Motor Capacity Sanyo brand servo motors 4 axis 5.8KW servo motor (feeding wire 2.3KW, bending 1.5KW, cutter 1KW, left or right movement 1KW Cutter Ability iron wire diameter 6mm Suitable for wire diameter 2-6mm iron wire standard Machine Dimension 2800*850*1500mm Machine Weight 950kgs Data Storage Quantity 10000 groups, 300pcs actions are one group Wire Feeding Speed 90m/minute Maximum Bending Speed 300r/minute, Angle ±180 degree Actions Directions Inner Mold: move lower and upper; Outer mold: move lower and upper. Directions are clockwise and counterclockwise. Production Speed 20-25pcs/minute(take example 200*200mm square shape) Bending Prcision ±0.5mm Wire Feeding Precision ±0.5mm Welding Module 40KW Welding transformer Manipulator clamp: 2sets Move Stroke Horizontal is 1000, cross is 100mm, vertical is 500mm Machine Model 2-6mm Servo System Maximum Bending 99N.M Control Screen Touch Screen PLC 1 Mechanical Functions 1)This machine's mechanical actions controlled by computer programs. 2)Automatic wire feeding, straightening and cutting, and bending and shaping, and butt welding. 3)Each shape is formed by maximum 300pcs of actions to realize. Machine Mechanism: 1)Wire feeding, bending and cutting, up and down by servo motor. 2)Control system we use PLC+Touch Screen, easy to operate, guarantee the stability, can preset production quantity, can program and edit data based on needs. 3) Servo system is high precision, high torque, high speed, to guarantee production speed. 4)Machine has alarm and emergency stop functions. Safe. Guarantee: one year, lifetime technical support Your side provide product drawings in dwg. format, before shipment we will programme these products and store in the computer.